Home / R&R Academy / Case Studies

Case Studies

Participate in a Case Study

Has R&R helped you make a minor product or process change or a complete system overhaul? Want to share your thoughts with your fellow casters?

Email our marketing team at: Marketing@ransom-randolph.com.

Ceramic Shell

Additives Impact Shell Properties (Matrixcote® system)

The addition of fibers and polymers used in the Matrixcote system slurries positively impacted shell properties

-

Fibers

-

Increased shell thickness

-

-

Polymers

-

Increased green strength and green deflection (elasticity) of the shell to reduce shell cracking during dewax

-

Decreased post fired shell strength to aid in shell removal

-

-

Fibers and polymers

-

Offered potential for coat reduction due to increased shell strength and thickness per coat

-

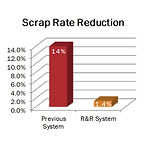

Complete System Conversion

Within a month of converting the primary slurry to Primcote binder, Foundry F

requested a proposal for a complete system overhaul

-

Reduced coats from 9 to 7

-

Reduced scrap rate from 14% to 1.4%

-

Annual material savings: $19,200

-

Created more uniform edges

-

Eliminated 2 backup coats from existing process

-

Labor savings: $50,000 (approx.)

-

Eliminated 1,000 hours of labor time

-

-

Reduced scrapped parts

-

Savings: $37,000 (approx.)

-

Foundry 1

-

Significantly improved slurry life to 22 months (more than 3 times previous slurry)

-

20% cost reduction versus previous slurry

-

Reduced costs associated with dumping and rebuilding slurry

Foundry 2

-

Significantly improved slurry life to 9 months (nearly 5 times previous slurry)

-

32% cost reduction versus previous slurry

-

Reduced post fired strength by 35%

-

Increased permeability by 128%

-

Reduced cracking on round ring parts

-

Significantly decreased scrap and rework with positive metal on parts

-

Eliminated gas defects on certain parts

-

Reduced make up time from 60+ minutes to 20 minutes

-

Simplified slurry maintenance

Solid Mold

-

Reduced mold cracking

-

33% increase in green (wet) compressive strength

-

Reduced finishing coats and improved as-cast surface finish

-

Surface tension agents reduce air bubble defects

-

Tighter tolerances, plus reduced warping and cracking

-

Superior thermal stability